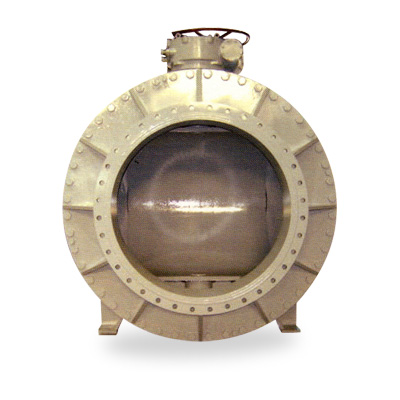

Ball Valve (Segment Type)

- There is no friction of the seat when the disc opens and closes.

- Both the disc seat and the body seat can be made of metal.

- Applicable to high temperature, high viscosity, and powder form.

- Standard

-

- 200㎜ ~ 1,350㎜ (※ According to customer requirements, small diameters of 1,650㎜ or less can be manufactured.)

- Working pressure

-

- 4.5kgf/㎠ ~ 20kgf/㎠

- Operation method

-

- manual, electric, pneumatic pressure, hydraulic pressure

- Installation method

-

- Perforation without water blockage, supply water line & sewage line

- Main part material

-

- GCD450, SS400, SC410, SSC13

Main part material

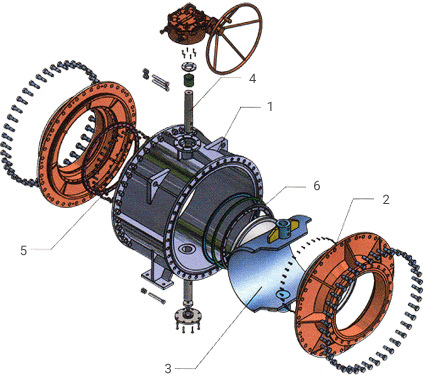

| No | Part name | Code | Meterial |

|---|---|---|---|

| 1 | Body | KS D4302 (Ductile Iron) | GCD450 |

| KS D3503 (Steel Structure) | SS400 | ||

| KS D3515 (Steel Welding Structure) | SWS400 | ||

| KS D4101 (Steel Casting) | SC410, SC450 | ||

| KS D4103 (Stainless Steel Casting) | SSC13 | ||

| 2 | Closure | KS D4302 (Ductile Iron) | GCD450 |

| KS D3503 (Steel Structure) | SS400 | ||

| KS D3515 (Steel Welding Structure) | SWS400 | ||

| KS D4101 (Steel Casting) | SC410, SC450 | ||

| KS D4103 (Stainless Steel Casting) | SSC13 | ||

| 3 | Ball | KS D4302 (Ductile Iron) | GCD450 |

| KS D3503 (Steel Structure) | SS400 | ||

| KS D3515 (Steel Welding Structure) | SWS400 | ||

| KS D4101 (Steel Casting) | SC410, SC450 | ||

| KS D4103 (Stainless Steel Casting) | SSC13 | ||

| 4 | Shaft | KS D3706 (Stainless Steel Bar) | STS304, STS420J2 |

| 5 | Body Seat | KS D3705 (Hot Rolled Stainless Steel Sheet) | STS304 |

| 6 | Ball Seat | KS M6613 (Rubber goods for water works) | NBR, EPDM, VITON, si-rubber |

| KS D6024 (Copper & copper cast-alloy) | ALBC |

※ Relevant standards apply to standards equivalent to or higher than international standards such as KS, AWWA, JIS, BS, and DIN

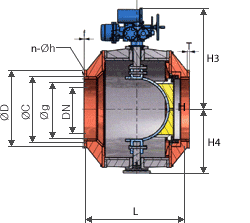

External dimensions

| Nominal diameter | Face-to-face distance | Flange size (KS D3578 F15) | External size | External size | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | L | ØD | Øg | ØC | n-Øh | T × F | X | H2 | H3 | H4 | Y | Z | 4-Øh |

| 200 | 320 | 342 | 264 | 295 | 8-23 | 24 × 2 | - | 297 | 352 | 240 | - | - | - |

| 300 | 505 | 464 | 367 | 400 | 12-23 | 27 × 3 | - | 328 | 468 | 330 | - | - | - |

| 400 | 560 | 582 | 477 | 515 | 16-27 | 29 × 3 | - | 382 | 626 | 375 | - | - | - |

| 500 | 700 | 706 | 582 | 620 | 20-27 | 31 × 3 | 450 | 411 | 688 | 455 | 600 | 200 | 4-23 |

| 600 | 845 | 810 | 682 | 725 | 20-30 | 34 × 3 | 550 | 444 | 805 | 570 | 700 | 200 | 4-23 |

| 700 | 1000 | 928 | 797 | 840 | 24-30 | 34 × 3 | 620 | 505 | 990 | 665 | 900 | 250 | 4-27 |

| 800 | 1160 | 1034 | 904 | 950 | 24-33 | 36 × 3 | 720 | 505 | 1080 | 775 | 1000 | 300 | 4-27 |

| 900 | 1300 | 1156 | 1004 | 1050 | 28-33 | 38 × 3 | 810 | 555 | 1200 | 890 | 1100 | 300 | 4-27 |

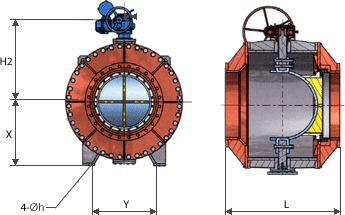

| Nominal diameter | Face-to-face distance | Flange size (KS D3578 F15) | External size | External size | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | L | ØD | Øg | ØC | n-Øh | T × F | X | H2 | H3 | H4 | Y | Z | 4-Øh |

| 1000 | 1420 | 1262 | 1111 | 1160 | 28-36 | 42 × 3 | 940 | 1478 | 845 | 580 | 1200 | 250 | 4-33 |

| 1100 | 1700 | 1366 | 1200 | 1270 | 32-36 | 45 × 3 | 990 | 1495 | 865 | 580 | 1300 | 350 | 4-33 |

| 1200 | 1750 | 1470 | 1304 | 1387 | 32-36 | 45 × 3 | 1080 | 1680 | 985 | 640 | 1400 | 300 | 4-33 |

| 1350 | 1790 | 1642 | 1462 | 1552 | 36-40 | 51 × 3 | 1140 | 1755 | 1035 | 640 | 1500 | 450 | 4-33 |

1. This specification table has been prepared based on the maximum external angle size and is subject to change without notice for product improvement.

2. The above drawing is a dimensional illustration and does not regulate the design structure.

3. Diameter according to KS B2305 (nominal diameter and hole diameter of valve).

4. The dimensional tolerance of the flange is in accordance with KS B1052, and the specifications of the flange are in accordance with KS D3578, KS B1511 or consultation with the purchaser.