Vertical Mixed Flow Pump

- Features

-

- The installation area is small.

- The installation method of the pump can be selected as one-phase or two-phase type.

- There is no need for a vacuum pump, and there is little risk of motor flooding.

- Low center of gravity of the product designed to minimize vibration and noise.

- The vortex prevention plate is attached to the suction pipe, so there is little vibration caused by the vortex.

- It is designed and manufactured for easy maintenance.

- It is possible to select submersible bearings suitable for the site conditions.

- Self-lubrication : Submersible Bearing

- Fresh water lubrication : Rubber Bearing

- Grease lubrication : Metal Bearing

- Standard Specifications

-

- Total pump head : 4~15m

- Flow rate : 10~1000㎥/min

- Temperature : 0~45℃

- Diameter : 300~2500㎜

- Purpose

-

- For general industry

- For sewage, wastewater treatment

- For dock drainage

- Circulating water for power plant

- For flood drainage

- For agricultural water intake

Specification

| Item | Standard | Remark / Option | |

|---|---|---|---|

| Design specification | diameter | Ø300㎜ ~ Ø2400㎜ | |

| flow rate | 8㎥/min ~ 850㎥/min | ||

| lift | 1.5m ~ 100m | ||

| power | 15㎾ ~ 2000㎾ | ||

| pumping fluid temp. | 0 ~ 45℃ | ||

| material | Casing | gray cast iron (GC200) | gray cast iron + nickel (GC200 + Ni 1~2%) |

| Impeller | Stainless Steel Cast Steel (SSC13) | Bronze(BC6), Bronze (AIBC3) | |

| Shaft | Carbon steel for machine structural use (SM45C) | Stainless Steel (STS304) | |

| Discharge curved pipe | cold rolled steel pipe (SS400) | gray cast iron + nickel (GC200 + Ni 1~2%) | |

| Production specifications | impeller type | Mixed Flow / Semi-Open, Closed | |

| Shaft Seal | Grease Packing | Mechanical Seal | |

| Coupling | Sleeve Coupling, Flange Flexible Coupling | ||

| Thrust Bearing | Taper Roller Bearing, Ball Bearing | ||

| Pump Bearing | Submersible Bearing | self-lubrication | |

| Rubber Bearing | External water supply lubrication (protective tube type) | ||

| Metal Bearing | grease lubrication | ||

| discharge flange | KS 10㎏/㎠ - F.F Type | KS 16㎏/㎠ - R.F Type | |

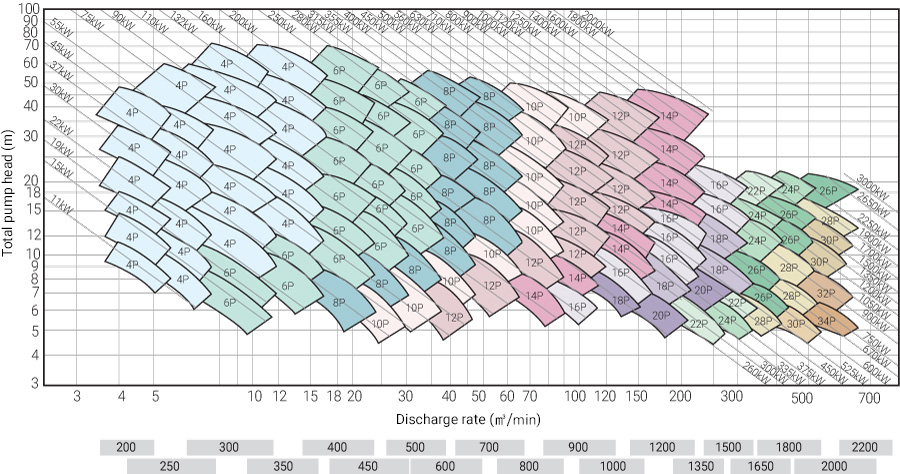

Selection table

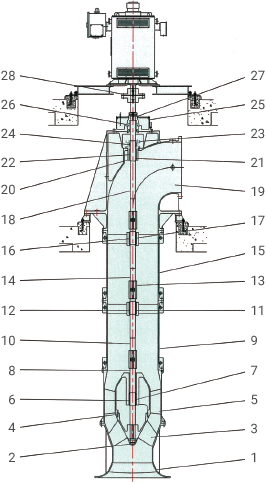

Material of main parts

| No. | Part Name | Material |

|---|---|---|

| 1 | Suction pipe | GC200 |

| 2 | Impeller nut | SSC13 |

| 3 | Impeller | SSC13 |

| 4 | Casing Wear Ring | BC6 |

| 5 | Guide Casing | GC200 |

| 6 | Casing Sleeve | STS304 |

| 7 | Casing Submersible Bearing | - |

| 8 | Pump Shaft | SS400 |

| 9 | Lower Pumping Pipe | GC200 |

| 10 | Lower Line Shaft | STS304 |

| 11 | Lower Pumping Pipe Sleeve | STS304 |

| 12 | Lower Pumping Pipe Submersible Bearing | - |

| 13 | Middle Coupling | SC42 |

| 14 | Upper Line Shaft | STS304 |

| 15 | Upper Pumping Pipe | GC200 |

| 16 | Upper Pumping Pipe Sleeve | STS304 |

| 17 | Upper Pumping Pipe Submersible Bearing | - |

| 18 | Upper Shaft | STS304 |

| 19 | Discharge Curved Pipe | GC200 |

| 20 | Stuffing Box | GC200 |

| 21 | Stuffing Box Sleeve | STS304 |

| 22 | Stuffing Box Submersible Bearing | - |

| 23 | Gland | BC6 |

| 24 | Grease Packing | Cotton + Grease |

| 25 | Bearing Housing | GC200 |

| 26 | Thrust Bearing | - |

| 27 | Bearing Adapter | SC42 |

| 28 | Flexible Coupling | GC200 |

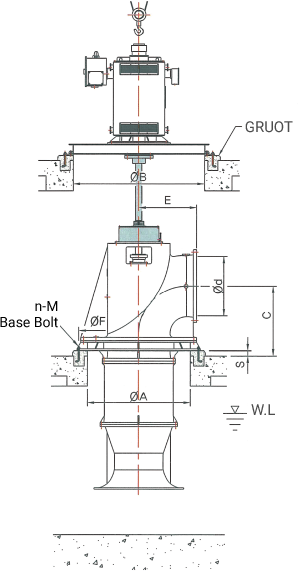

Flexible Coupling

| Diameter : d | A | B | C | E | G | S | F | n | M |

|---|---|---|---|---|---|---|---|---|---|

| 350㎜ (14inch) | 700 | 1300 | 450 | 500 | 1250 | 70 | 1050 | 6 | M24 |

| 400㎜ (16inch) | 800 | 1400 | 530 | 550 | 1380 | 70 | 1150 | 6 | M24 |

| 450㎜ (18inch) | 900 | 1500 | 600 | 600 | 1550 | 70 | 1250 | 6 | M24 |

| 500㎜ (20inch) | 1050 | 1500 | 630 | 650 | 1630 | 70 | 1400 | 8 | M24 |

| 600㎜ (24inch) | 1100 | 1700 | 700 | 750 | 1800 | 70 | 1500 | 8 | M30 |

| 700㎜ (28inch) | 1250 | 1900 | 800 | 850 | 1950 | 70 | 1650 | 8 | M30 |

| 800㎜ (32inch) | 1400 | 2100 | 900 | 950 | 2150 | 70 | 1800 | 8 | M30 |

| 900㎜ (36inch) | 1550 | 2300 | 1000 | 1000 | 2350 | 90 | 1950 | 8 | M30 |

| 1000㎜ (40inch) | 1750 | 2400 | 1200 | 1050 | 2600 | 90 | 2200 | 12 | M30 |

| 1200㎜ (48inch) | 2050 | 2600 | 1400 | 1200 | 2850 | 90 | 2500 | 12 | M30 |

| 1350㎜ (54inch) | 2300 | 2900 | 1550 | 1350 | 3150 | 120 | 2750 | 12 | M36 |

| 1500㎜ (60inch) | 2600 | 3000 | 1700 | 1500 | 3350 | 120 | 3050 | 16 | M36 |

| 1600㎜ (64inch) | 2900 | 3300 | 1850 | 1600 | 3550 | 120 | 3400 | 16 | M36 |

| 1800㎜ (70inch) | 3100 | 3600 | 2000 | 1700 | 3750 | 150 | 3600 | 16 | M42 |

| 2000㎜ (80inch) | 3300 | 4000 | 2200 | 1900 | 3950 | 150 | 3800 | 16 | M42 |

| 2200㎜ (90inch) | 3500 | 4400 | 2400 | 2100 | 4200 | 150 | 4000 | 16 | M42 |