Sumersible Axial Flow Pump

- Features

-

- It is optimally designed and manufactured for low-head and high-flow rate drain pumps.

- Easy to install and maintain with compact and lightweight design.

- Easy to install and maintain with compact and lightweight design.

- As ancillary equipment is not required, the size of the pumping station is greatly reduced, thereby reducing equipment costs.

- It is possible to replace the existing vertical pump with a submersible pump without any structural changes.

- It uses impellers with perfect dynamic balancing and hydraulic balance.

- In the event of an abnormality, the abnormal part can be identified early by the monitoring system.

- Standard Specifications

-

- Total Pump Head : 4~30m

- Flow Rate : 13~600㎥/min

- Temperature : 0~45℃

- Diameter : 350~2000㎜

- Purpose

-

- for sewage & drainage

- for drainage of rainwater pumping station

- for agricultural pumping & drainage station

- to prepare for preventing from flooding or heavy rain

- for inflow and discharge pumps of sewage treatment plants, etc.

Specification

| Item | Standard | Remark / Option | |

|---|---|---|---|

| Design Specification | Diameter | Ø350㎜ ~ Ø2000㎜ | |

| Flow Rate | 13㎥/min ~ 600㎥/min | ||

| Lift | 1.5m ~ 20m | ||

| Power | 15㎾ ~ 1000㎾ | ||

| Pumping Fluid Temp. | 0 ~ 45℃ | ||

| Maretial | Guide Casing | Gray Cast Iron (GC200) | Gray Cast Iron + Nickel (GC200 + Ni 1~2%) |

| Propeller / Impeller | Stainless Steel Cast Steel (SSC13) | Aluminum Bronze (AIBC3) | |

| Shaft | Stainless Steel (STS410) | ||

| Motor Frame | Gray Cast Iron (GC200) | Gray Cast Iron + Nickel (GC200 + Ni 1~2%) | |

| Production Specifications | Impeller Type | Axial Flow / Mixed Flow | |

| Shaft Seal | Double Mechanical Seal | Cartridge Double Bellows Seal | |

| Bearing | Ball Bearing | ||

| Motor Specifications | Motor Type | Air Filled Watertight | |

| Insulation class | F, B | ||

| Pump Starting Method | Star Delta Or Line Start | Auto Transformer | |

| Sensor |

|

||

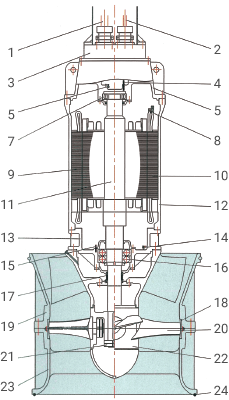

Selection Table

Material Of Main Parts

| No. | Part Name | Material |

|---|---|---|

| 1 | Main Cable | PNCT |

| 2 | Sensor Cable | PNCT |

| 3 | Bracket | GC200 |

| 4 | Upper part bearing temperature sensor | - |

| 5 | Terminal box leak detection sensor | - |

| 6 | Terminal box | GC200 |

| 7 | Upper part bearing | Steel |

| 8 | Motor stator temperature sensor | - |

| 9 | Stator | SI |

| 10 | Rotor | SI |

| 11 | Pump Shaft | STS410 |

| 12 | Frame | GC200 |

| 13 | Bearing Housing | GC200 |

| 14 | Motor internal leak detection sensor | - |

| 15 | Lower part bearing temperature sensor | - |

| 16 | Lower part bearing | Steel |

| 17 | Double Mechanical Seal | SIC/SIC |

| 18 | Wear Ring | BC6 |

| 19 | Guide Casing | GC200 |

| 20 | Propeller Blade | SSC13 |

| 21 | Propeller Boss Nut | STS304 |

| 22 | Propeller Boss | GC200 |

| 23 | Suction Pipe | GC200 |

| 24 | Anti-vibration O-ring | Rubber |

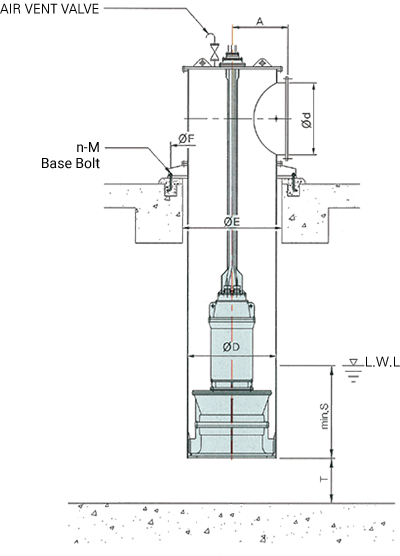

External Dimensions

| Diameter:d | A | D | E | S | T | Pump Base | ||

|---|---|---|---|---|---|---|---|---|

| F | n | M | ||||||

| 350㎜ (14inch) | 430 | 700 | 1000 | 1050 | 700 | 1250 | 6 | 24 |

| 400㎜ (16inch) | 450 | 700 | 1000 | 1050 | 700 | 1300 | 6 | 24 |

| 450㎜ (18inch) | 500 | 800 | 1100 | 1200 | 800 | 1350 | 6 | 24 |

| 500㎜ (20inch) | 550 | 800 | 1100 | 1200 | 800 | 1500 | 6 | 24 |

| 600㎜ (24inch) | 600 | 900 | 1200 | 1350 | 900 | 1550 | 8 | 30 |

| 700㎜ (28inch) | 650 | 900 | 1200 | 1350 | 900 | 1650 | 8 | 30 |

| 800㎜ (32inch) | 750 | 1000 | 1300 | 1500 | 1000 | 1750 | 8 | 30 |

| 900㎜ (36inch) | 800 | 1200 | 1500 | 1800 | 1200 | 1950 | 8 | 30 |

| 1000㎜ (40inch) | 900 | 1200 | 1600 | 1800 | 1200 | 2100 | 12 | 30 |

| 1200㎜ (48inch) | 1050 | 1400 | 1800 | 2100 | 1400 | 2400 | 12 | 36 |

| 1350㎜ (54inch) | 1100 | 1600 | 2000 | 2400 | 1600 | 2400 | 12 | 36 |

| 1500㎜ (60inch) | 1150 | 1800 | 2200 | 2700 | 1800 | 2450 | 12 | 36 |

| 1600㎜ (64inch) | 1200 | 1800 | 2200 | 2700 | 1800 | 2550 | 12 | 36 |

| 1800㎜ (70inch) | 1300 | 2000 | 2400 | 3000 | 2000 | 2750 | 12 | 36 |

| 2000㎜ (80inch) | 1500 | 2400 | 2800 | 3600 | 2400 | 2550 | 16 | 36 |

| 2200㎜ (90inch) | 1700 | 2600 | 3000 | 3900 | 2600 | 2750 | 16 | 36 |