Double Suction Volute Pump

- Features

-

- High efficiency and wide range of usage.

- Quiet operation and less trouble in operating

- It is easy to disassemble and inspect as the pump casing has an upper and lower separate structure.

- It uses a ball bearing and is easy to repair and maintain by using a grease lubrication method.

- It uses impellers with perfect dynamic balancing and hydraulic balance.

- Use the impeller wear ring that can maintain with the highest efficiency and repair it with easy way.

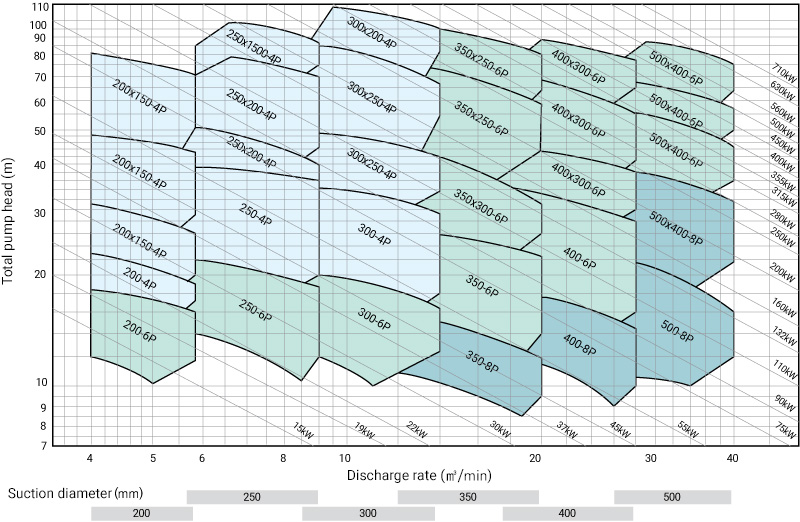

- Standard Specifications

-

- Total Pump Head : 5~120m

- Flow Rate : 2~300㎥/min

- Temperature : 0~80℃

- Diameter : 150~1500㎜

- Purpose

-

- For general industry purpose

- for water supply and sewage

- for fire extinguishing equipment

- for irrigation of agriculture purpose

- for circulating water in power plant

- for water supply and drainage

Specification

| Item | Standard | Remark / Option | |

|---|---|---|---|

| Design Specification | Diameter | Ø150㎜ ~ Ø1500㎜ | |

| Flow Rate | 2㎥/min ~ 300㎥/min | ||

| Lift | 5m ~ 120m | ||

| Power | 7.5㎾ ~ 1000㎾ | ||

| Pumping Fluid Temp. | 0 ~ 80℃ | ||

| Material | Casing | Gray Cast Iron (GC200) | Gray Cast Iron + Nickel (GC200 + Ni 1~2%) |

| Impeller | Stainless Steel Cast Steel (SSC13) | Bronze (BC6), Aluminum Bronze (AIBC3) | |

| Shaft | Carbon steel for machine structural us (SM45C) | Stainless Steel (STS304) | |

| Common base metal | Cold Rolled Steel Pipe (SS400) | ||

| Production Specifications | Impeller Type | Closed | |

| Shaft Seal | Grease Packing | Mechanical Seal | |

| Coupling | Flange Flexible Coupling, Grid Coupling | ||

| Bearing | Ball Bearing | ||

| Discharge Flange | KS 10kg/㎠ - R.F Type | KS 16kg/㎠ - R.F Type | |

Selection Table

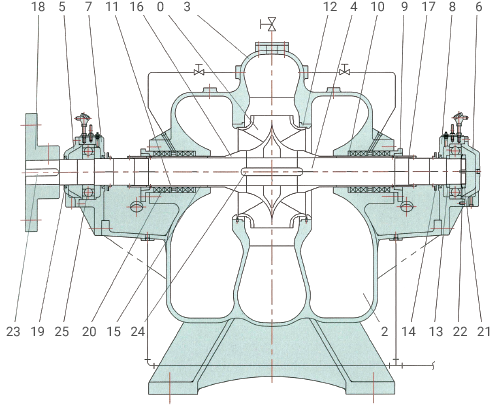

Material of Main Parts

| No. | Part Name | Material |

|---|---|---|

| 1 | Impeller | SSC13 |

| 2 | Lower Part Casing | GC200 |

| 3 | Upper Part Casing | GC200 |

| 4 | Pump Shaft | STS304 |

| 5 | Bearing Housing (coupling side) | GC200 |

| 6 | Bearing Housing (opposite-coupling side) | GC200 |

| 7 | Bearing Cover (coupling side) | GC200 |

| 8 | Bearing Cover (opposite-coupling side) | GC200 |

| 9 | Gland | GC200 |

| 10 | Packing Seat | STS304 |

| 11 | Lantern ring | STS304 |

| 12 | Casing wear ring | BC6 |

| 13 | Wear ring seat | STS304 |

| 14 | Deflector | BC6 |

| 15 | Packing Sleeve | STS304 |

| 16 | Packing Sleeve | STS304 |

| 17 | Sleeve Nut | STS304 |

| 18 | Pump Shaft Coupling | GC200 |

| 19 | Oil Seal | NBR |

| 20 | Gland Packing | TEFLON |

| 21 | Bearing Nut | STS304 |

| 22 | Bearing Washer | STS304 |

| 23 | Impeller Key | STS304 |

| 24 | Coupling Key | STS304 |

| 25 | Bearing | STEEL |