Manhole Cutter Pump

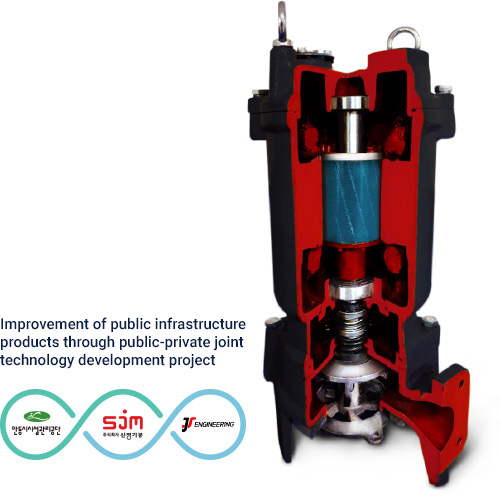

Purpose of product improvement To improve products through joint technology development to promote efficient maintenance and cost reduction of public infrastructure and to contribute to revitalizing the local economy.

- Features

-

Classification Features Effect Impeller Type Non-Clog (One Vane) Smooth transfer of foreign substances and foreign substances Cutter Type Single Cutter Cutting of foreign substances (long fibers or solid substances, etc.) during suction, eliminating clogging on the suction side (improving suction conditions by securing suction area) Addition of function Grinding Groove Prevents contaminants from being wound around the cutter and shaft Improvement of suction performance Cutter Plate Smoothly passes through sludge and contaminants

- Technical Competitivenes

-

Classification Details Durability The main parts are made of stainless steel, which is strong against corrosion. Economical Reduced maintenance cost and easy to replace parts by extending the replacement cycle Reduced maintenance cost and easy to replace parts by extending the replacement cycle Suitable for water purification plants, sewage treatment plants, sewage relay pumping stations, manhole pumping stations, etc.

- Applicable Field

-

Classification Applicable field Environmental field Sewage treatment plant, relay pump station, village sewage, small-scale sewage relay, manhole pump station, etc. Agricultural & livestock farming industry Field Pumping plant, livestock manure sludge transfer, etc. Architecture & building construction field Large restaurants, buildings (Apartments/buildings) and public facilities for wastewater transportation, etc.

- Usage

-

- For transporting wastewater and sewage sludge

Field usage cases

Field usage cases by type

The field use cases below are reference cases that occur due to the inflow of unknown water (wet tissues, diapers, etc.) in residential areas and large restaurants due to the characteristics of manhole pumping stations.

-

Spurt Pump The wide impeller blade makes it easy to pass solids. (The price is more expensive than the improved product.)

Spurt Pump The wide impeller blade makes it easy to pass solids. (The price is more expensive than the improved product.) -

Vortex When the size of contaminants (solids) is small, it is transported smoothly. (In the case of long or large contaminants, they block the entrance and cause a decrease in suction performance.)

Vortex When the size of contaminants (solids) is small, it is transported smoothly. (In the case of long or large contaminants, they block the entrance and cause a decrease in suction performance.) -

Grinder It cuts contaminants into small pieces on the suction side and is suitable for small flow rate transfer. (Due to the size of the grinder, the suction port area is narrow and the suction flow rate is low.)

Grinder It cuts contaminants into small pieces on the suction side and is suitable for small flow rate transfer. (Due to the size of the grinder, the suction port area is narrow and the suction flow rate is low.) -

Existing Cutter It is easy to transfer foreign substances after the first cut of foreign substances. (A phenomenon occurs where uncut impurities are wound around the cutter.)

Existing Cutter It is easy to transfer foreign substances after the first cut of foreign substances. (A phenomenon occurs where uncut impurities are wound around the cutter.)

Improved product

This developed product was developed and installed as a prototype at a manhole pumping station (Myeongji District) managed by the Andong City Facilities Management Corporation, and after about 17 months of field testing, a patent application was completed and commercialized.

-

Features of the improved cutter pump As the single cutter rotates and cuts the suctioned contaminants and then transports them, it eliminates the clogging and winding of the pump suction side, making it easy to maintain.

Features of the improved cutter pump As the single cutter rotates and cuts the suctioned contaminants and then transports them, it eliminates the clogging and winding of the pump suction side, making it easy to maintain.

Materials

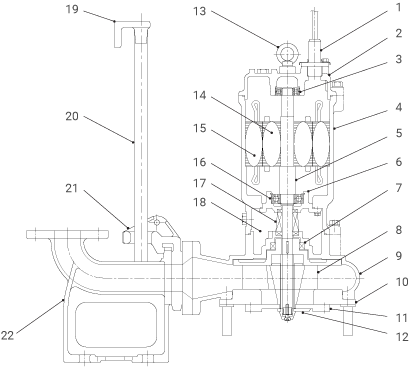

| No. | Part Name | Material |

|---|---|---|

| 1 | Cable Tube | N.B.R |

| 2 | Bracket GC | 200 |

| 3 | Upper Bearing | STB 2 |

| 4 | Frame | GC 200 |

| 5 | Shaft | STS 410 |

| 6 | Bearing Housing | GC 200 |

| 7 | Oil Seal | N.B.R |

| 8 | Impeller | SSC 13 |

| 9 | Casing | GC 200 |

| 10 | Suction Cover | GC 200 |

| 11 | Cutter Plate | SSC 13 |

| 12 | Cutter | Hi-Cr |

| 13 | Eye Bolt | SS 275 |

| 14 | Rotor | S - 60 |

| 15 | Stator | S - 60 |

| 16 | Lower Bearing | STB 2 |

| 17 | M/C Seal | SIC / SIC |

| 18 | Oil | Turbine Oil |

| 19 | Guide Support | GC 200 |

| 20 | Guide Pipe | STS 304 |

| 21 | Guide Hook | GC 200 |

| 22 | Duck Foot Bend | GC 200 |

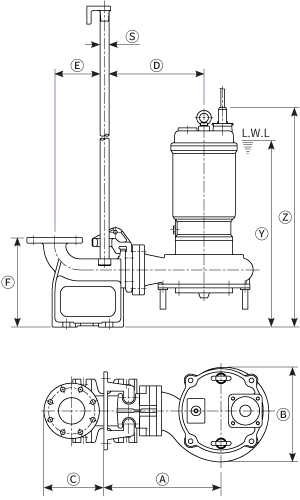

Dimensions

| MODEL | A | B | C | D | E | F | S | Y | Z |

|---|---|---|---|---|---|---|---|---|---|

| ASJC-2-8 | 388 | 219 | 168 | 228 | 140 | 250 | 25 | 484 | 584 |

| ASJC-2-15 | 388 | 219 | 168 | 228 | 140 | 250 | 25 | 484 | 584 |

| ASJC-2-22 | 454 | 291 | 168 | 258 | 140 | 250 | 25 | 539 | 654 |

| ASJC-2-37 | 454 | 291 | 168 | 258 | 140 | 250 | 25 | 539 | 654 |

| ASJC-3-55 | 505 | 319 | 257 | 285 | 225 | 285 | 32 | 636 | 801 |

| ASJC-3-75 | 505 | 319 | 257 | 285 | 225 | 285 | 32 | 636 | 801 |

| ASJC-4-110 | 622 | 377 | 285 | 345 | 275 | 305 | 32 | 749 | 922 |

| ASJC-4-150 | 622 | 377 | 285 | 345 | 275 | 305 | 32 | 749 | 922 |

Specifications

| Diameter (㎜) | Model | Output (㎞) | Total Pump Head (m) | Discharge Rate (㎥/min) | Rotation Speed (rpm) | Weight (㎏) |

|---|---|---|---|---|---|---|

| 50 | ASJC-2-8 | 0.75 | 4.5 | 0.2 | 1750 | 65 |

| ASJC-2-15 | 1.5 | 8.5 | 0.2 | 1750 | 70 | |

| ASJC-2-22 | 2.2 | 15 | 0.2 | 1750 | 75 | |

| ASJC-2-37 | 3.7 | 15 | 0.4 | 1750 | 85 | |

| 80 | ASJC-3-55 | 5.5 | 10 | 0.8 | 1750 | 110 |

| ASJC-3-75 | 7.5 | 12 | 0.85 | 1750 | 120 | |

| 100 | ASJC-4-110 | 11 | 12 | 1.8 | 1750 | 220 |

| ASJC-4-150 | 15 | 15 | 1.8 | 1750 | 240 |

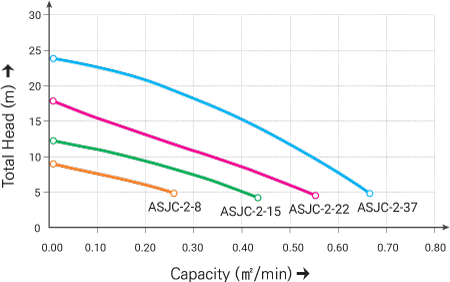

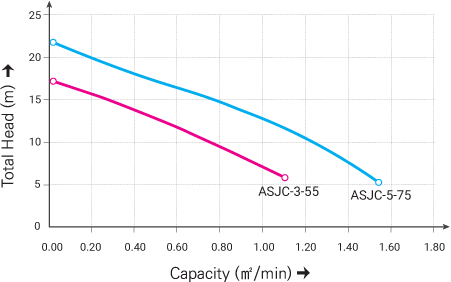

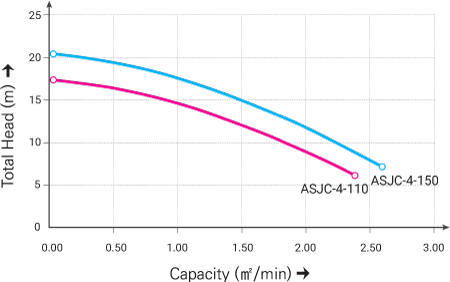

Performance Curve